VW 6 Speed DSG Transmission: Complete Guide, Issues & Maintenance

The VW 6-speed DSG transmission is a dual-clutch gearbox that blends the smoothness of an automatic with the control of a manual. It uses two clutches to pre-select gears, allowing for quick and efficient shifts without a clutch pedal. This design delivers faster gear changes and improved fuel efficiency compared to many traditional automatics.

Since its debut in 2003, the 6-speed DSG—often referred to by its code DQ250—has been used in a wide range of Volkswagen, Audi, Skoda, and SEAT models. It is designed to handle engines with up to 350 Nm of torque, with some later versions supporting up to 400 Nm. Its combination of performance and convenience has made it a popular choice in both everyday vehicles and sportier models.

While the DSG offers a refined driving experience, it also has specific maintenance needs and known issues that owners should understand. From mechatronic unit wear to clutch servicing, knowing how it works and what to expect can help extend its lifespan and keep it performing at its best.

What Is the VW 6 Speed DSG Transmission?

The Volkswagen 6-speed DSG transmission is a dual-clutch gearbox that uses two separate clutches to manage odd and even gears. It delivers fast gear changes with minimal power loss while allowing both fully automatic operation and manual gear selection. It is widely used in VW models for its balance of performance, efficiency, and smooth operation.

Overview of Direct Shift Gearbox Technology

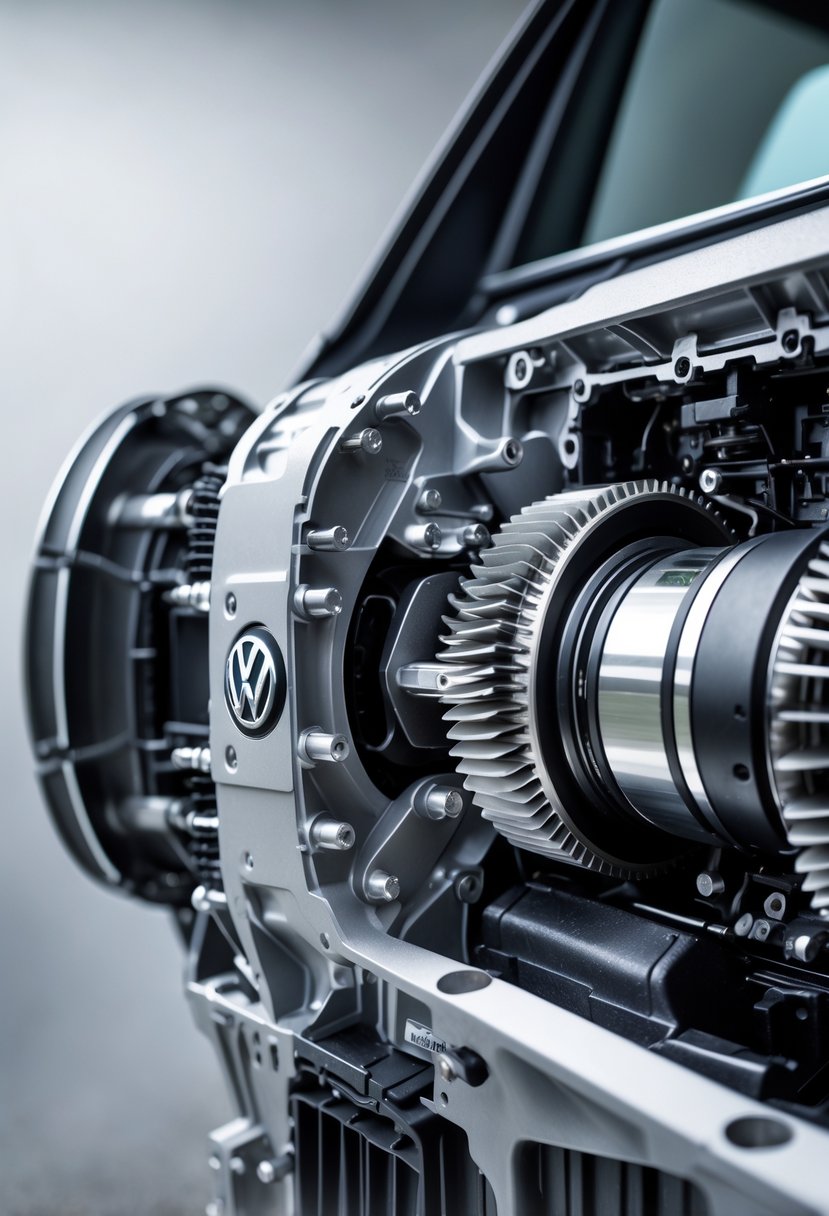

The 6-speed DSG, known internally as the DQ250, is a dual-clutch transmission developed by Volkswagen. It combines two electronically controlled manual gearboxes into one unit.

One clutch (K1) manages gears 1, 3, and 5. The other (K2) handles gears 2, 4, and 6. This setup allows the next gear to be pre-selected before the shift occurs.

The clutches are a wet clutch type, meaning they are lubricated and cooled by transmission fluid. A Mechatronic unit controls shifting, using data such as engine speed, throttle position, and vehicle speed to determine the optimal gear.

This design reduces shift times to around 200 milliseconds and helps maintain engine power delivery during gear changes.

Key Features and Benefits

The VW 6-speed DSG offers quick, smooth shifts without the delay often felt in traditional automatics. Drivers can choose between automatic mode or manual control via the gear lever or steering wheel paddles.

Notable advantages include:

- Fuel efficiency comparable to or better than manual transmissions in many cases

- Sport mode for more aggressive shift patterns and higher RPM holding

- Dual operation for both comfort and performance driving

- Compact transaxle design that integrates the differential and gearbox in one housing

Its torque capacity is rated at about 295 lb-ft in factory form, making it suitable for a wide range of VW and Audi models, including performance-oriented versions like the GTI and GLI.

Comparison With Conventional Automatic Transmissions

Unlike a torque-converter automatic, the DSG uses clutches instead of a fluid coupling. This means less energy loss between the engine and wheels.

Shifts are faster and more direct, often improving acceleration times compared to manual versions of the same car.

In everyday driving, the DSG can shift smoothly at low RPM for comfort, yet respond quickly under hard acceleration. Traditional automatics tend to have slower shifts and less precise gear control.

However, DSG systems require specific maintenance, such as regular fluid changes, to maintain smooth operation and reliability.

6-Speed Automatic w/DSG & Tiptronic

The 6-speed DSG (Direct Shift Gearbox) is a dual-clutch transmission that combines the efficiency of a manual with the convenience of an automatic. It uses two clutches to pre-select gears, allowing very quick shifts with minimal power loss.

This system does not use a traditional torque converter. Instead, it engages gears through electronically controlled clutches and hydraulics. The control unit monitors factors like engine speed, road speed, and throttle position to select the optimal gear.

Tiptronic is a manual shift mode built into the automatic system. In this mode, the driver can change gears manually using the gear lever or steering wheel-mounted paddles. This gives more control over acceleration and engine braking when needed.

Key differences between DSG and a conventional automatic include:

| Feature | DSG 6-Speed | Standard Automatic (Torque Converter) |

|---|---|---|

| Gear Change Speed | Very fast (fractions of a second) | Slower |

| Clutch Type | Dual-clutch | Torque converter |

| Manual Mode | Tiptronic / Paddle Shifters | Often available, but less direct |

| Efficiency | Higher in most driving conditions | Lower due to torque converter losses |

DSG can operate fully automatically for comfort or in Tiptronic mode for driver control. This flexibility makes it suitable for both everyday driving and more performance-focused situations.

6-speed DSG DQ250 transmission VW PASSAT / Golf VI / Golf VII

The DQ250 is a 6-speed dual-clutch transmission used in many Volkswagen models, including the Passat, Golf VI, and Golf VII. It uses a wet clutch system designed to handle up to 350 Nm of torque.

Volkswagen introduced the DQ250 in 2003, and it has been used in both front-wheel drive (02E) and all-wheel drive (0D9) configurations. It is paired with engines ranging from 1.6L to 3.2L.

Common service tasks include:

- Transmission fluid changes every 40,000 miles (approx. 64,000 km)

- Filter replacements for the heat exchanger and ATF system

- Seal and ring replacements during reassembly to prevent leaks

A simplified spec table:

| Feature | Detail |

|---|---|

| Type | 6-speed wet-clutch DSG |

| Torque capacity | Up to 350 Nm |

| Drive types | FWD (02E) / AWD (0D9) |

| First use | 2003 |

| Typical service | Oil + filter every 40k miles |

Some owners report jerking, shuddering, or shifting delays, often linked to worn clutches, faulty solenoids, or mechatronic unit issues. The mechatronic unit controls gear selection and clutch operation, and in some cases, replacing only the control board can fix problems without replacing the full unit.

Regular maintenance helps extend the life of the DQ250 and prevent costly repairs. Neglecting oil changes or filter service can lead to contamination that damages solenoids and clutch components.

VW 6 Speed DSG Transmission Issues

The Volkswagen 6-speed DSG (Direct Shift Gearbox) is known for quick gear changes and good fuel efficiency. However, some owners have reported mechanical and electronic problems that can affect performance and drivability.

Common issues include:

- Shifting delays during acceleration or deceleration

- Rough or jerky gear changes at various speeds

- Gear slipping under load

- Warning lights on the dashboard

- Difficulty engaging reverse

In some cases, drivers notice unusual noises such as grinding, whining, or clunking during shifts. Others report vibrations when accelerating, which may point to clutch or mechatronics problems.

A few frequent causes include:

| Cause | Possible Effect |

|---|---|

| Low or contaminated fluid | Overheating, poor lubrication |

| Worn clutch packs | Slipping, rough shifts |

| Faulty mechatronics unit | Erratic shifting |

| Electrical faults | Incorrect gear selection |

Repair costs can vary. Minor fixes, such as fluid changes, are relatively inexpensive, while clutch or mechatronics replacement can cost several thousand dollars.

Volkswagen has issued recalls in the past for problems such as mechatronics failures, clutch actuator faults, and fluid leaks. These recalls aimed to prevent loss of power, gear disengagement, or overheating.

Addressing symptoms early can reduce repair costs and prevent safety risks. Regular maintenance, including timely fluid changes, helps reduce the likelihood of major DSG issues.

Is 6 Speed VW DSG Transmission Reliable

The 6-speed VW DSG, often the DQ250 model, is known for quick gear changes and good fuel efficiency. Many owners report smooth performance when the unit is serviced on schedule.

Reliability depends heavily on regular maintenance, especially fluid and filter changes every 40,000 miles. Skipping these services can lead to clutch wear or mechatronic unit issues.

Common problems include:

- Juddering or shuddering during acceleration

- Delayed gear engagement when shifting into drive or reverse

- Overheating warnings in heavy traffic

- Limp mode activation due to detected faults

Later versions of the DQ250 have improved clutch materials and updated mechatronic components. These updates reduce some early reliability concerns but do not remove the need for proper care.

| Issue Type | Possible Cause | Typical Repair Cost (USD) |

|---|---|---|

| Mechatronic failure | Electrical or hydraulic faults | $1,500–$2,500 |

| Clutch pack wear | High mileage or fluid neglect | $1,000–$1,800 |

| Fluid contamination | Missed service intervals | $250–$400 (fluid change) |

Drivers who avoid extended creeping in traffic and allow the transmission to warm up often see fewer problems. Consistent servicing and gentle driving habits can help the 6-speed DSG last well beyond 150,000 miles.

Technical Design and Internal Components

The 6-speed Volkswagen DSG transmission uses a dual-clutch layout, electronically controlled hydraulics, and integrated gearing to deliver quick and efficient shifts. Its design combines elements of a manual gearbox with automated control, allowing it to pre-select gears and manage power delivery without driver input.

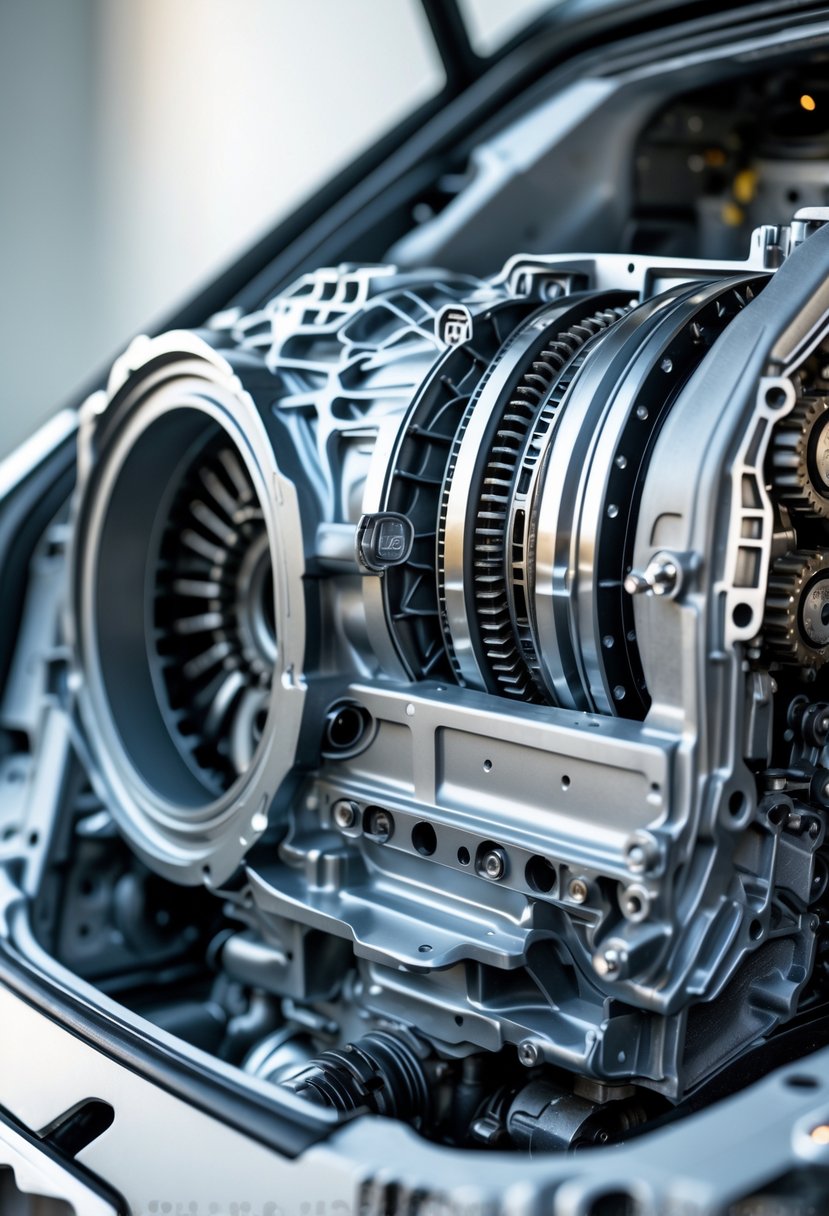

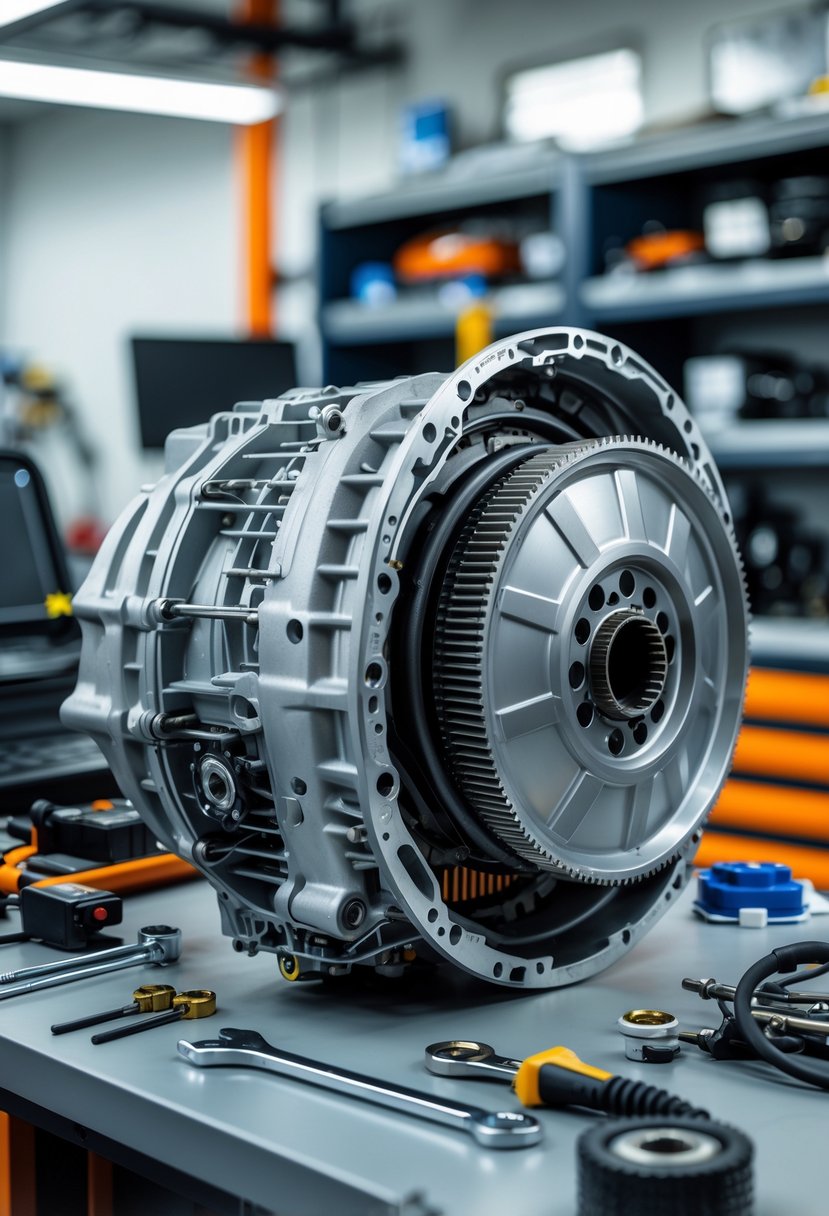

Dual-Clutch System and Clutch Packs

The DSG uses two separate multi-plate clutch packs, labeled K1 and K2.

K1 operates the odd-numbered gears (1, 3, 5), while K2 handles the even-numbered gears (2, 4, 6) and reverse.

Both clutches are concentric, meaning one sits inside the other on the same axis.

This arrangement allows the transmission to engage one gear while pre-selecting the next, reducing shift time.

Most 6-speed DSG units use a wet clutch design. The friction plates run in transmission fluid for cooling and lubrication. Hydraulic pressure, controlled by the mechatronics unit, applies and releases the clutches.

This setup improves durability under load and allows smooth engagement during low-speed driving.

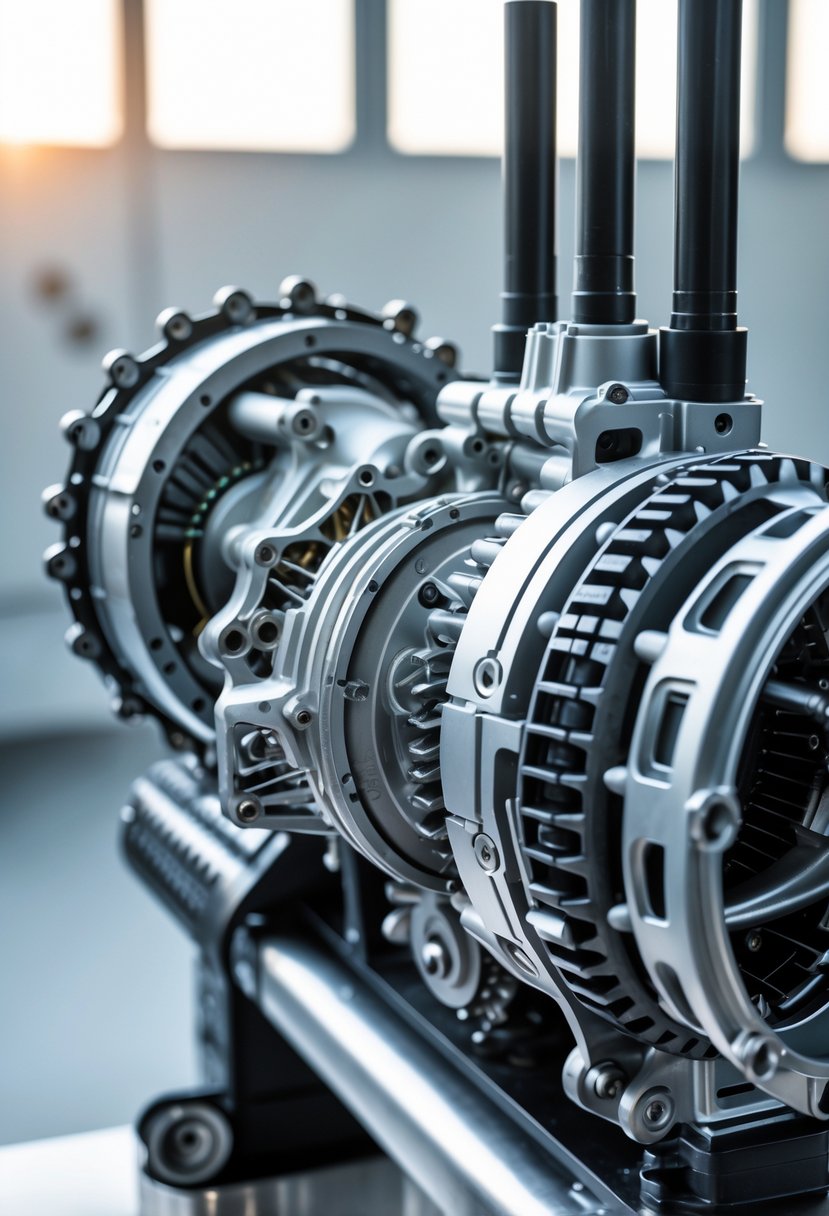

Input and Output Shafts

The transmission contains two input shafts—one inside the other—linked to the respective clutch packs.

The outer shaft connects to K1 and drives the odd gears, while the inner shaft connects to K2 for even gears.

Each input shaft meshes with its own set of gears on the output shaft.

When a gear is engaged, torque flows from the engine through the clutch, into the input shaft, then to the output shaft, and finally to the differential.

This dual-shaft arrangement makes it possible to have two gears ready at once.

It also reduces power interruption during shifts, as one clutch can engage while the other disengages almost instantly.

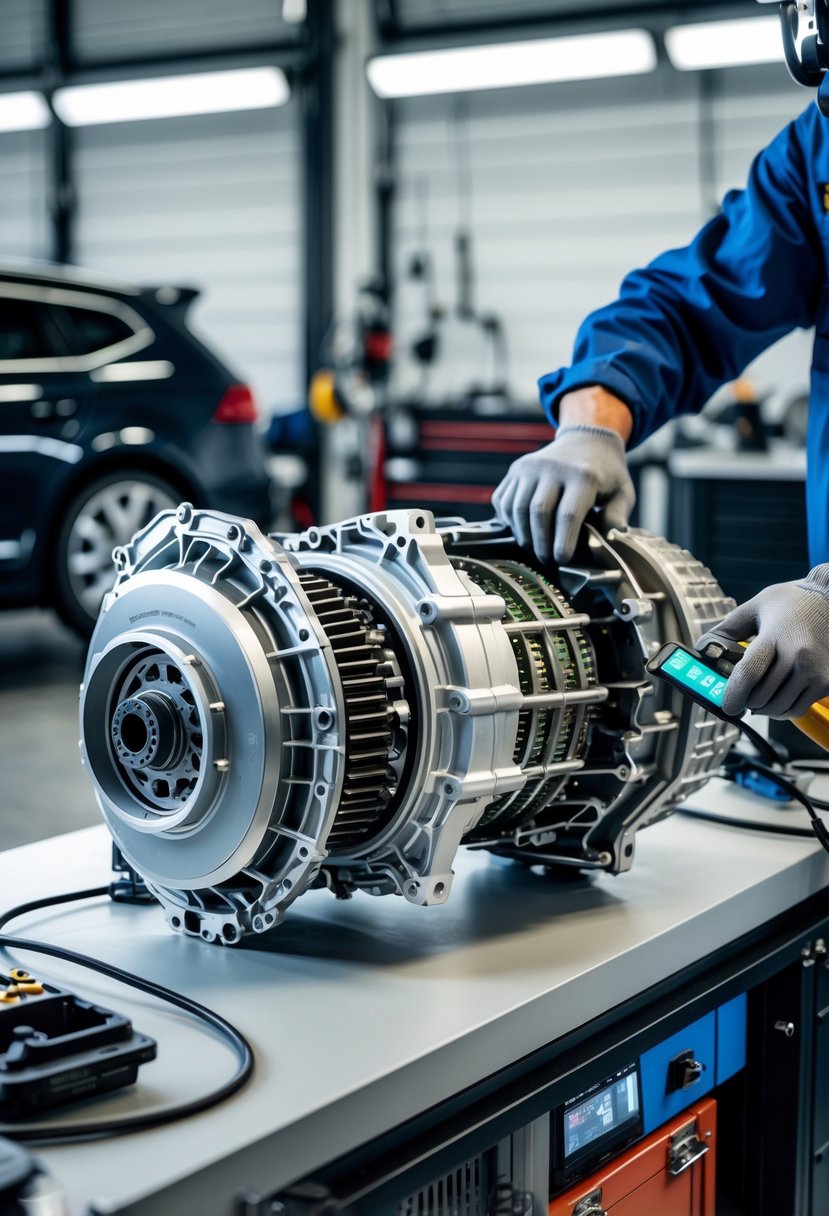

Mechatronics Unit and Electronics

At the heart of the DSG’s control system is the mechatronics unit.

This module combines the hydraulic valve body, sensors, and the Transmission Control Unit (TCU) into one assembly.

The TCU monitors inputs such as engine speed, throttle position, brake pressure, and vehicle speed.

It uses this data to determine when and how to shift, as well as how much clutch pressure to apply.

Hydraulic pressure from the unit actuates the clutches and gear selectors.

The electronics communicate with the engine control unit (ECU) and ABS system via the CAN bus, allowing coordinated control of power delivery and braking.

Differential and Gear Ratios

The DSG is a transaxle design, meaning the differential is housed in the same casing as the gears.

It splits torque between the drive wheels and uses the same lubrication system as the gearbox.

Gear ratios are chosen to balance acceleration, fuel economy, and engine efficiency.

Lower gears have shorter ratios for stronger acceleration, while higher gears are taller to reduce engine RPM at cruising speeds.

In all-wheel-drive versions, a transfer case is attached to the differential to send power to the rear wheels.

The integration of the differential within the transmission case saves space and reduces weight compared to separate units.

How the VW DSG Transmission Works

The 6-speed VW DSG transmission uses two clutches to manage odd and even gears separately, allowing one gear to engage while the next is pre-selected.

Its operation depends on a combination of hydraulic pressure, electronic controls, and integration with the vehicle’s driving systems for smooth and efficient gear changes.

Gear Shifting Mechanism

The DSG uses a dual-clutch setup made up of the K1 and K2 clutch packs.

K1 controls 1st, 3rd, and 5th gears, while K2 handles 2nd, 4th, and 6th gears.

When the driver accelerates, one clutch transmits power through the engaged gear while the other clutch pre-selects the next gear.

This design allows gear changes to happen in fractions of a second without a noticeable power drop.

The gearbox has two input shafts—one inside the other—linked to the clutches.

Each shaft drives a separate set of gears, which connect to the output shafts.

This layout combines the mechanical efficiency of a manual transmission with the convenience of automatic shifting.

Hydraulic and Electronic Control

The DSG uses a mechatronic unit, which integrates the transmission control module (TCM) and hydraulic valve body.

The TCM processes data from sensors, including engine speed, vehicle speed, throttle position, and clutch temperature.

Hydraulic pressure, managed by 11 solenoids, moves shift forks and engages clutches.

The system also controls cooling oil flow to prevent clutch overheating during heavy use.

Sensors such as input speed, output speed, and oil temperature feed real-time data to the TCM.

If a sensor fails, backup readings from the ABS wheel-speed sensors or engine-speed sensor maintain operation.

This combination of electronics and hydraulics ensures precise, consistent shifts under varying driving conditions.

Integration With Driving Modes

The DSG adapts its shifting behavior based on selected driving modes and driver input.

In “Normal” mode, it shifts early for fuel efficiency, keeping engine RPM lower.

In “Sport” mode, it holds gears longer for quicker acceleration.

Manual mode allows the driver to select gears using paddle shifters or the gear lever.

The TCM still prevents damaging shifts, such as downshifting at excessive speeds.

During stop-and-go traffic, the DSG can engage 1st gear smoothly without excessive clutch slip.

On highways, it shifts into higher gears quickly to reduce fuel consumption and engine load.

This flexibility makes it suitable for both everyday commuting and more spirited driving.

Common Issues and Symptoms

The VW 6-speed DSG transmission can develop mechanical, hydraulic, and electronic faults that affect driving performance. Problems often show up as changes in how the gearbox shifts, unexpected loss of power, or visible signs of wear such as leaking fluid.

Shifting Delays and Rough Shifting

Some drivers notice a pause when moving from park to drive or reverse. This delay can last a second or more, making low-speed maneuvers harder.

Rough or harsh shifting is another frequent issue. Instead of smooth gear changes, the transmission may jolt, thud, or shudder during acceleration. This often occurs when clutch packs wear or the mechatronics unit malfunctions.

Electronic faults can also cause inconsistent shift timing. A faulty sensor or outdated transmission control software may trigger slow or unpredictable gear changes.

Key signs include:

- Noticeable lag when selecting a gear

- Sudden jerks during upshifts or downshifts

- Increased noise during gear changes

Addressing these symptoms early can prevent further wear on clutch components and reduce repair costs.

Slipping Gears and Warning Lights

Gear slipping happens when the transmission disengages unexpectedly, often during acceleration. The engine revs rise, but speed does not increase as expected. This can reduce control and make overtaking unsafe.

Slipping may be caused by worn clutch packs, low fluid pressure, or internal mechanical faults. In some cases, the mechatronics unit fails to engage the correct gear.

Transmission warning lights often appear alongside slipping issues. These lights indicate stored fault codes in the transmission control module. Common related codes point to clutch performance problems, solenoid faults, or hydraulic pressure errors.

Possible effects:

| Symptom | Potential Cause | Risk |

|---|---|---|

| Gear disengages under load | Worn clutch | Loss of power |

| Warning light stays on | Electronic fault | Reduced performance |

| Engine revs without speed gain | Low fluid pressure | Overheating risk |

Prompt diagnosis is essential to avoid full gearbox failure.

Overheating and Fluid Leaks

The 6-speed DSG uses a wet-clutch system that relies on transmission fluid for cooling and lubrication. Low fluid levels or degraded fluid can cause overheating, leading to clutch damage and erratic shifting.

Fluid leaks are a common source of low levels. Leaks may occur at seals, gaskets, or cooler lines, leaving red or brown spots under the vehicle.

Overheating can also result from blocked fluid passages or a failing oil pump. When the system overheats, the transmission may enter limp mode to protect itself, limiting speed and gear range.

Signs of overheating or leaks include:

- Burning smell after driving

- Visible fluid under the car

- Transmission temperature warnings on the dashboard

Regular fluid checks and timely seal repairs can prevent costly internal damage.

Causes of Transmission Problems

Many failures in the VW 6-speed DSG transmission come from issues with fluid condition, clutch component wear, or faults in its control systems. These problems can lead to shifting delays, gear slippage, or loss of power if not addressed quickly.

Low or Contaminated Transmission Fluid

The DSG relies on transmission fluid for lubrication, cooling, and hydraulic pressure. Low fluid levels can cause overheating and increased friction between internal parts.

Contaminated fluid, often containing metal shavings or debris, can block internal passages and reduce performance. This contamination usually comes from normal wear but can accelerate if other components are failing.

Signs of fluid issues include delayed gear engagement, rough shifts, or a burning smell.

Regular checks are important since DSG fluid degrades faster under heavy driving or high temperatures.

Prevention tips:

- Follow VW’s fluid change intervals (often every 40,000 miles).

- Use only the specified DSG fluid type.

- Inspect for leaks around the transmission housing.

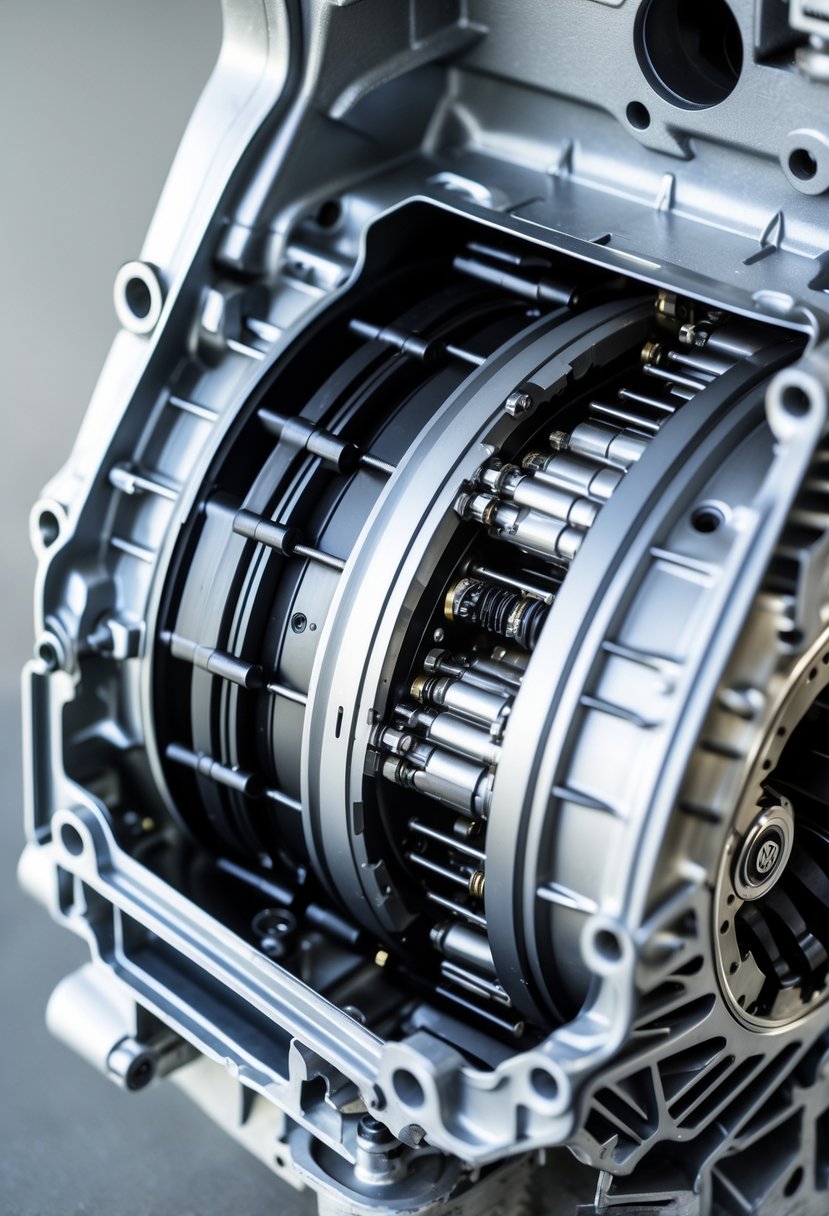

Worn Clutch Packs

The 6-speed DSG uses two multi-plate clutch packs to engage odd and even gears separately. Over time, friction material on these clutches wears down, reducing grip and causing slippage.

Worn clutch packs can lead to harsh shifting, hesitation, or the gearbox failing to hold a gear under load. Drivers may also notice increased engine revs without matching acceleration.

Clutch wear often happens sooner in stop-and-go traffic or when towing. If ignored, it can damage other drivetrain components.

Replacement involves removing the transmission and installing new clutch assemblies, which can be costly. Regular servicing and avoiding excessive slipping during starts can extend clutch life.

Mechatronics and Electrical Failures

The mechatronics unit is the DSG’s electronic-hydraulic control module. It manages clutch engagement and gear selection. A faulty unit can cause erratic shifting, failure to select gears, or the transmission entering limp mode.

Electrical issues, such as damaged wiring or failing sensors, can disrupt signals between the mechatronics and the engine control unit. This can trigger warning lights or prevent the gearbox from operating correctly.

Common causes include heat damage, fluid contamination entering the control unit, or manufacturing defects.

Repairs may involve replacing the mechatronics unit or repairing wiring harnesses after diagnostic testing.

Prompt attention to warning signs can prevent full transmission failure and reduce repair costs.

Maintenance and Longevity Tips

Keeping a VW 6-speed DSG transmission in good condition depends on timely fluid replacement, careful monitoring of clutch wear, and ensuring the control software operates correctly. Each of these factors directly affects shift quality, component life, and repair costs.

Regular Fluid Checks and Replacement

The 6-speed DSG uses a wet clutch system, which relies on specific transmission fluid to lubricate and cool internal parts. This fluid also acts as a hydraulic medium for gear changes.

Volkswagen generally recommends replacing the DSG fluid and filter every 40,000 miles. In heavy traffic, towing, or aggressive driving, fluid can degrade faster, making earlier service—around 20,000–30,000 miles—beneficial.

Old or contaminated fluid can cause:

- Jerky or delayed shifts

- Overheating of clutch packs

- Reduced fuel efficiency

Technicians measure and refill the exact fluid volume, as overfilling or underfilling can cause shifting issues. Owners should also check for leaks around the transmission housing during routine inspections.

Clutch Pack Inspection and Service

The clutch pack in a 6-speed DSG handles alternating engagement of odd and even gears. Over time, friction material wears down, especially in high-mileage or stop-and-go driving.

Signs of clutch wear include:

- Slipping under acceleration

- Shuddering during take-off

- Noticeable drop in shift smoothness

During scheduled service, mechanics can inspect clutch pack wear through access points or during fluid changes. If wear is detected early, replacement can be limited to the clutch pack rather than the entire transmission.

Using the correct DSG fluid and avoiding excessive heat buildup helps extend clutch life. Drivers who regularly tow or drive in traffic should consider more frequent inspections.

Software Updates and Diagnostics

The DSG’s mechatronic unit controls clutch engagement, shift timing, and hydraulic pressure. Software updates from Volkswagen can improve shift quality, fix calibration errors, and prevent certain faults.

A diagnostic scan during service can:

- Detect stored fault codes

- Monitor clutch adaptation values

- Identify early mechatronic issues

Updating the control module ensures the transmission operates with the latest parameters. This can reduce wear on mechanical parts and improve fuel efficiency.

Specialized tools are required for adaptation resets after fluid or clutch service. Skipping this step can lead to rough shifting or delayed gear engagement. Professional servicing is recommended for these procedures.

Driving Experience and Performance

The VW 6-speed DSG transmission delivers quick gear changes without interrupting power from the engine. It blends the smoothness of an automatic with the control of a manual, making it adaptable for both relaxed commuting and more engaged driving.

Impact on Everyday Driving

In daily use, the DSG shifts quickly and smoothly, often faster than a traditional automatic. This helps reduce hesitation when accelerating from a stop or merging into traffic.

Because it uses two clutches, one gear is always pre-selected, which limits shift lag. This improves responsiveness in city driving and during short bursts of acceleration.

Fuel efficiency can also benefit. The transmission’s ability to keep the engine in its optimal power range means fewer wasted revs and more consistent performance.

Drivers may notice slight hesitation or a “creep” delay at very low speeds, especially in stop-and-go traffic. This is a common trait of dual-clutch systems and not necessarily a fault.

Key everyday benefits:

- Smooth, predictable shifts

- Improved fuel economy compared to some automatics

- Quick response when accelerating

Sporty and Manual Mode Capabilities

The DSG offers a Sport mode that holds gears longer and downshifts more aggressively. This keeps the engine in a higher RPM range, which can improve acceleration and throttle response.

In manual mode, the driver can control gear changes using paddle shifters or the gear lever. Shifts happen almost instantly, with minimal delay between input and engagement.

This setup allows for precise control during spirited driving, such as on winding roads. The quick shifts help maintain momentum without upsetting the car’s balance.

For track or performance use, the DSG can deliver consistent shift times without the variability of a human-operated clutch. However, it lacks the mechanical feel of a traditional manual, which some drivers may prefer for engagement.

Frequently Asked Questions

The VW 6-speed DSG transmission is known for quick gear changes and good fuel efficiency, but it has specific maintenance needs and potential problem areas.

It operates differently from a traditional automatic and comes in several versions, each used in different Volkswagen models.

What are the common issues with the VW DSG transmission?

Owners often report rough or delayed shifting, especially during low-speed driving.

Other common problems include slipping gears, warning lights on the dashboard, and difficulty engaging reverse.

Faults in the mechatronics unit, worn clutch packs, or low transmission fluid are frequent causes.

How does the DSG gearbox compare to a standard automatic transmission?

A DSG uses two clutches to pre-select gears, allowing faster shifts than a torque converter automatic.

This design can improve acceleration and fuel economy.

However, it is more complex and may require more specialized maintenance.

Can you explain the differences between DSG and DCT systems?

A DSG is a type of dual-clutch transmission (DCT) developed by Volkswagen.

While all DSG units are DCTs, not all DCTs are DSGs.

The main differences are in design details, control software, and manufacturer-specific components.

What should I know about driving a car with a DSG gearbox?

DSG gearboxes often perform best when the driver uses smooth throttle inputs.

They may feel different from traditional automatics, especially at low speeds, where shifts can seem abrupt.

Regular fluid changes are important to keep the system working as intended.

How can I identify which DSG gearbox model is in my vehicle?

The gearbox type is usually listed on a sticker in the trunk or service manual.

VW’s common 6-speed DSG is the DQ250, while some models use 7-speed versions like the DQ200 or DQ381.

A technician can also identify the unit by checking the transmission code.

What VW models come equipped with the DSG transmission?

The 6-speed DSG appears in many VW models, including the Golf GTI, Passat, Jetta GLI, and Tiguan.

It is also used in some Audi, Skoda, and SEAT vehicles under different brand names.

Availability depends on the model year, trim level, and market.

![Volkswagen Jetta Air Conditioning Not Working [Reasons + Fixed]](https://volkswagenbuddy.com/wp-content/uploads/2024/05/volkswagen-jetta-air-conditioning-not-working-reasons-fixed_3896-768x531.jpg)

![2008 Volkswagen Beetle Starts Then Shuts Off [A Quick Fix]](https://volkswagenbuddy.com/wp-content/uploads/2024/05/2008-volkswagen-beetle-starts-then-shuts-off-a-quick-fix_4516-768x531.jpg)

![2010 Volkswagen Routan Dvd Player Not Working [With Solution]](https://volkswagenbuddy.com/wp-content/uploads/2024/05/2010-volkswagen-routan-dvd-player-not-working-with-solution_3861-768x531.jpg)